Chemical processes involve risks. Protect your operators and our environment and use hermetically sealed gear pumps. Leak-proof, safe, and sustainable.

Let’s meet at WOTS in our booth at PumpPlaza (8D050). We will tell you all about it!

Magnetically coupled gear pumps

Hermetically sealed gear pumps are used for pulsation-free dosing, for pumping and circulating low to medium viscous, lubricating, and non-lubricating liquids. They are also suitable for acidic and corrosive solutions. Very accurate and reproducible.

Because the pumps are equipped with a magnetic coupling, the pumps are a reliable, leak-free solution for extremely high to extremely low temperatures.

Gear pumps are specifically configured for the reliability and accuracy of your application and are therefore reliable. Especially in these times with increasing delivery times, an investment in quality products benefits your operational reliability! Sustainable solutions!

Thanks to a wide range of material combinations (including corrosion-resistant components), and variable speed pump drives, these gear pumps are very versatile.

System pressure up to 325 bar

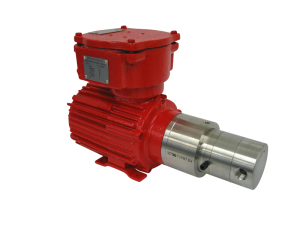

GATHER pump with magnetic coupling

GATHER magnetically coupled process pumps are unique in their ability to handle system pressure up to 325 bar! This makes them ideal for a variety of challenging applications, such as seal units, sample units and also cryogenic applications! Moreover, they are suitable for SIP & CIP applications.

Volume range from 0.000333 to 66.7 l/min

System pressure -1 to +325 bar

Temperature range -200 to +450°C

Viscosity from 0.1 to 2,000 mPas (specials up to 10,000 mPas)

Crystallizing, oxygen- and moisture-sensitive liquids

HNPM micropump, ATEX

The compact HNPM micro gear pumps have been developed for pulsation-free pumping of very small volumes, including non-lubricating, and inert liquids. For high pressure, low pressure, and OEM applications. The hermetically sealed micropumps ensure the safe pumping of crystallizing, oxygen- and moisture-sensitive liquids.

Leak-proof, safe! Micropumps for EX zones are also available.

Flow rates from 1 μl/hour to 1.1 l/min

Differential pressure from 1.5 to 200 bar

Viscosity from 0.3 to 1,000,000 mPas

Solidifying liquids

MAAG gear pumps with the MagDrive magnetic coupling also ensure safe and reliable applications such as crystallization, moisture- or air-sensitive liquids (e.g. isocyanate). The double sealing of the magnetic coupling ensures optimal heating and cooling and leak detection; ideal for coagulating liquids such as paraffin, and moleton sulphur.

Flow from 0.05 to 1,400 l./min.

System pressure -1 to 350 barg

Temperature from -30 °C to 320 °C

Viscosity 0.3 to 4,000000 mPas

Suurmond has specialized in gear pumps since 1974 and represents MAAG Pump & Filtration Systems AG, GATHER Industrie GmbH and HNP Mikrosysteme GmbH.

Want to know more about gear pumps and their role in reliable processes? We look forward to meeting you in our stand! PumpPlaza stand 8D050! Let’s talk!